FINDING TOP DEAD CENTRE (TDC)

ON MOTRONIC FLYWHEELS

Finding TDC on an engine is vital when installing aftermarket camshafts and ECU's. It's reasonably difficult on a Motronic equipped engine as there are no external marks. A common method is to put a screw driver down a plug hole, estimate when the piston is at TDC, then paint a mark on the harmonic balancer. This however, is all a bit agricultural and can lead to considerable error.Causes of error can include dwell of the piston at TDC, innacurate position of harmonic balancer pointer/mark and turning of the outer ring of the harmonic balancer over time.

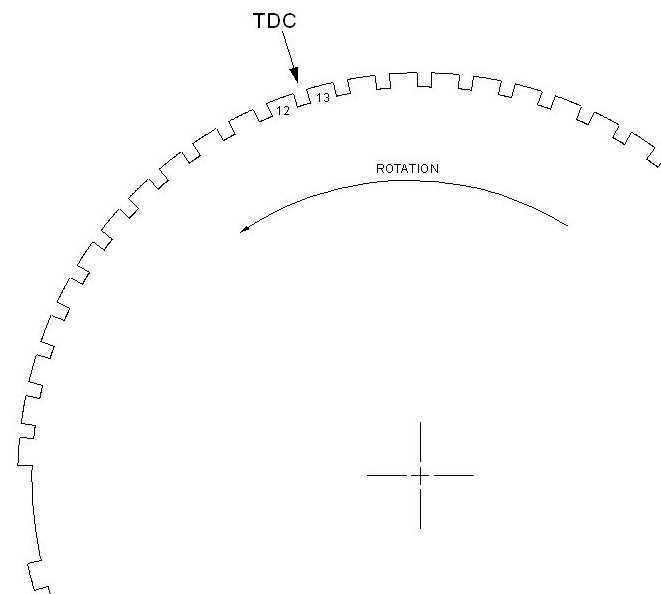

The method below is considerably more accurate. The Motronic flywheel makes a fantastic timing protractor. Being a larger diameter means accuracy is increased over using the harmonic balancer. The term 60-2 means there are 60 theoretical teeth, two of which are missing. Therefore, the tooth spacing must be 6 degrees.

Some of the earlier Jetronic equipped 8 valve PSA engines were fitted with a flywheel timing marker to allow adjustment of static timing by rotating the distributor. As Motronic systems are non-adjustable, the marker was discontinued. Luckily the dowel hole and tapped hole remained on later engine blocks, allowing fitting of the Jetronic timing marker. The marker has to be bent slightly however, in order to clear the Motronic teeth. The marker conveniently has 0 and 10 degree notches. The later particularly useful for confirming base ignition timing on aftermarket ECU's.

In the picture below the 8V marker has been bolted to an XU9J4 bolt using the 8V dowel and M7 bolt. On later XU10 blocks the marker is fixed using the same dowel and an M6 bolt. It's positioned at 0 degrees, TDC.

The marker is pointing at TDC which is half way between the 12th and 13th tooth after the two missing teeth. Paint the area white so it's easily identifiable with a timing light.