This aluminium wedge changes the angle of the normal XU9J4 exhaust so that it clears the bulkhead. It allows the standard 205 downpipe to bolt straight up to the XU9J4 exhaust headers.

This aluminium wedge changes the angle of the normal XU9J4 exhaust so that it clears the bulkhead. It allows the standard 205 downpipe to bolt straight up to the XU9J4 exhaust headers. 205 Mi16 and GTi6

CONVERSION PARTS

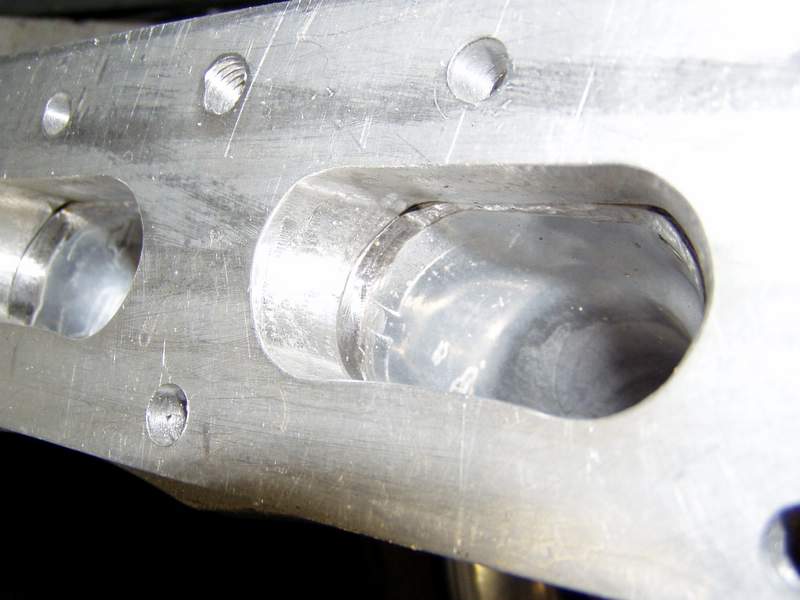

Mi16 Exhaust Wedge Plate

This aluminium wedge changes the angle of the normal XU9J4 exhaust so that it clears the bulkhead. It allows the standard 205 downpipe to bolt straight up to the XU9J4 exhaust headers.

This aluminium wedge changes the angle of the normal XU9J4 exhaust so that it clears the bulkhead. It allows the standard 205 downpipe to bolt straight up to the XU9J4 exhaust headers.

The wedge is machined on a CNC mill to and comes complete with tapered steel washers and new longer studs.

The wedge should be installed without gaskets. Loctite Copper Maxx is recommended as a sealant between both mating surfaces. No gaskets are used.

It's difficult to see in the picture, but there are tapered washers under the standard exhaust nuts. Failure to use these will mean constant tightening of nuts in difficult places.

GTi6 Exhaust Wedge Plate

The XU10J4RS as fitted to the GTi6 has a completely different exhaust port shape and stud spacing to the XU9J4. For this reason, the GTi6 wedge needs to do two things - change the angle and change the port shape. The GTi6 exhaust headers are a lovely piece of engineering and if you absolutely must have them, then this wedge will do the trick.

You can see from this picture that the port shape is very different. So much in fact, that the ports of the wedge need to be hand finished to match the blend perfectly.I also recommend blending the first 5-6mm of the GTi6 exhaust flange

You can see from this picture that the port shape is very different. So much in fact, that the ports of the wedge need to be hand finished to match the blend perfectly.I also recommend blending the first 5-6mm of the GTi6 exhaust flange

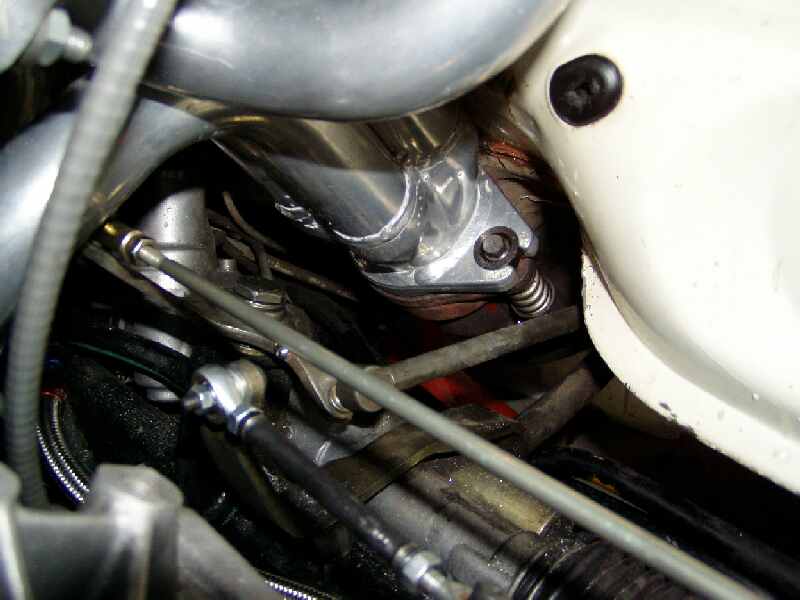

Fitting is also more difficult. The wedge is retained to the head by four socket head cap screws, in the usual top four holes. The GTi6 headers then bolt to the wedge via the five normal holes. Longer studs are used on the bottom five holes, which protrude through the wedge and GTi6 exhaust flange.

If like me, you like fitting engines by lifting from below, you'll find fitting even more of a challenge. The GTi6 pipes need to be laid in the tunnel then bolted to the wedge once the engine is in. It's far easier to drop the complete assembly in from the top.

Loctite Copper Maxx is recommended as a sealant. No gaskets are used. Comes with studs, bolts and tapered washers.

Space in the tunnel is very tight and you'll need to remove part of lip in the body. The amount to be removed depends on which block you're using. In this installation an XU10J4 block was used which raises the head approx. 10mm. Using an alloy block will be a lot easier.

Space in the tunnel is very tight and you'll need to remove part of lip in the body. The amount to be removed depends on which block you're using. In this installation an XU10J4 block was used which raises the head approx. 10mm. Using an alloy block will be a lot easier.

Shortened Inlet Manifold

I have done a few 205 conversions, both with and without the standard inlet manifold. From my personal experience I highly recommend the shortened inlet manifold. It gives a far neater and easier installation and allows the use of the standard throttle cable.

Some claim that the shortened inlet manifold effects the midrange torque. These shortened manifolds have been tested on a 405 Mi16x4 and absolutely no difference in performance could be felt. In a lighter car like the 205 any difference would be undetectable.

The manifold is shortened by 45mm and retains the mounting points for the fuel rail. The coil mounting points are deleted however, as it’s more convenient to use the standard 205 coil/ignitor setup, or upgrade to a multi-coil setup.